On July 11-th Volvo Trucks North America invited journalists from all over the world to their plant and newly opened Volvo Trucks Customer Centre in New River Valley, VA to unveil new Volvo VNL truck.

"The new Volvo VNL builds on our long-standing commitment to deliver the safest, most comfortable and most efficient long-haul truck on the market," said Göran Nyberg, president of Volvo Trucks North America. "Infused with innovations and technologies, we're proud to expand upon that commitment to our current and future customers with this new design."

Claes Nilsson, President of Volvo Trucks Corporation and other Sweden based high-rank managers also took part in VNL world premiere.

Claes Nilsson: "The Volvo brand is almost 90-year-old, the first truck we sold in North America was in the year 1959, and in the year 2016 Volvo Trucks sold almost 22,000 trucks here and about 130,000 globally. One big reason for our success is that we are leaders in innovations. Some examples: we were first with a safety belt, we were first with a turbo engine, an engine brake. The I-shift is among the most recent.

We have very ambitious target – to be number one – it doesn't mean that we want to be the biggest, but we want to be the best in the eyes of our customers, we want our customers to make more money and to be more successful than the customers of our competitors.

In 2016 and this year the volume is lower than it was in 2015. However, we have a very good expectation about our new products VNR and VNL. We also consider a service and aftermarket business in the USA as a very successful for Volvo Trucks. Even with a lower volume, the business for us is much healthier than it was 10-15 years ago. It allows us to invest here in a new product and our plant. For instance, we open a new state of the art paint shop at the plant here, and New Customer Service Centre."

According to Rob Simpson, Director Brand & Marketing Development Volvo Trucks North America no other truck manufacturers are using such an advanced technology in a paint shop but Volvo. Rob Simpson gave journalists a guided tour of plants assembly lanes were unionized workers every 18-hours deliver such a beautiful creature like a brand new VNR or VNL Volvo truck.

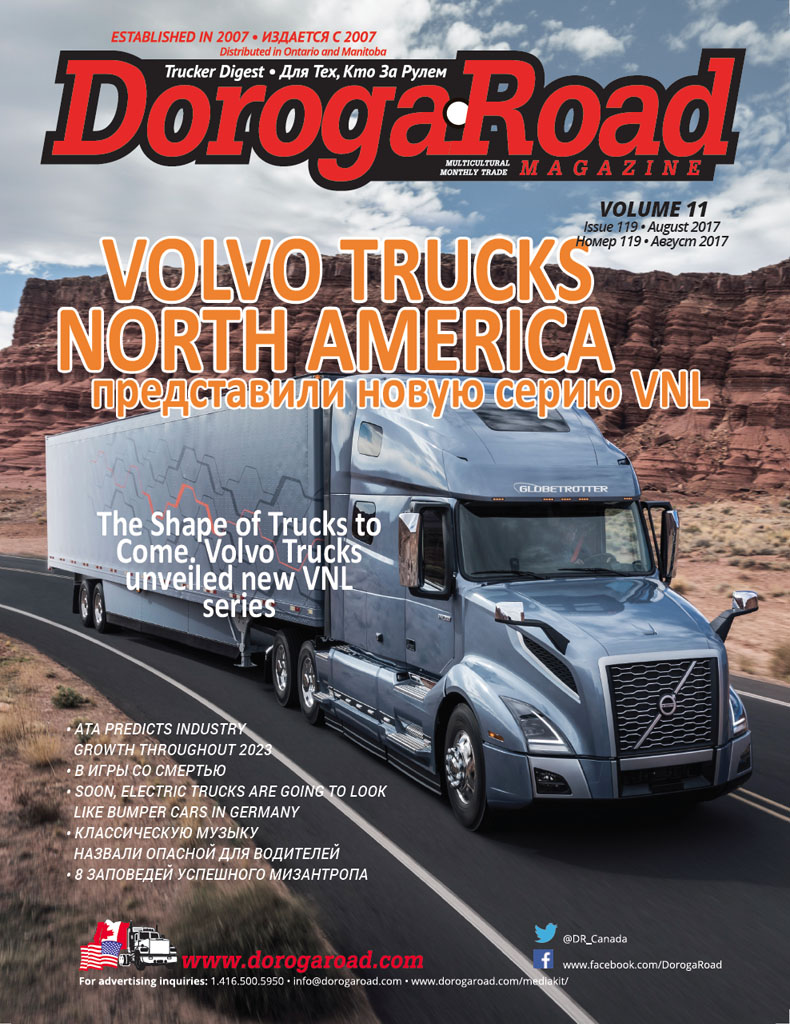

Striking Exterior Design

Rikard Orell, Design Director of Volvo Trucks, was also on hand: "In our US headquarters in Greensboro, NC we have a dedicated and passionate design team developing these great vehicles. They know North American customers and drivers very well, and they understand how truck used here in the USA. I'd like to talk about the emotional side of the design of a new VNL. We could describe our design strategy in five words. We want our truck to be bold, to stand out. We want it to be edgy, we don't feel afraid to be different, our design is noticeable, and we are innovative. It's not just the amount of modern technology, but rather how we apply this technology in a new and innovative way, solving real problems for real people. Volvo trucks are also modern trucks. We are not in a retro or nostalgia, we are looking into the future, and we are always to put a human in a center."

Designers of the new Volvo VNL combined elements of Volvo's design language with dynamic new features. Swept back headlights include signature Volvo daytime running lights and frame a bold new Volvo grille and hood that is 70 lbs lighter than on the previous model. Redesigned and repositioned engine air intakes allow for less turbulent intake air delivery. Airflow up and around the cab has also been optimized with new chassis and roof fairings.

"While we wanted the new VNL to make a statement on the road, we knew that it also had to make a statement to our customers' bottom lines" said Wade Long, director of product marketing for Volvo Trucks North America. "The incredible design elements that we've incorporated not only look great but they add value for the customer. Whether it's the sleek new bodywork that improves aerodynamics, or the new three-piece bumper that aids in repairability, every design change we've made has a purpose."

Productivity-Boosting Driver, Living Environments

"We relied on feedback from nearly 2,000 driver interviews to make sure the changes we were making aligned with drivers' needs," said Jason Spence, Volvo Trucks product marketing manager – long haul. "The results speak for themselves: our new VNL features the most comfortable, driver-friendly environment we've ever built."

That comfort extends to the four sleeper cab configurations available in the new Volvo VNL series. Designed to provide drivers a comfortable place to rest after a long day on the road, the sleeper options are packed with a number of space-saving, comfort-boosting innovations. Additionally, an all-new, full 70-inch sleeper is available in the Volvo VNL 760 and 740 models, taking Volvo's legendary comfort to an all-time high.

All VNL sleepers feature curved cabinets that open toward the back to maximize space, as well as an integrated, reclining bunk, which is a trucking industry first in North America. LED interior lighting reduces power consumption and provides softer lighting. A redesigned sleeper control panel allows drivers to control heating and cooling, and adjust the audio system from a more ergonomic position on the bunk. Also, drivers can lock the doors or activate a panic alarm if needed.

For the first time in North America, Volvo's Globetrotter trim levels will be available on the VNL 760 and VNL 860 sleeper models. Long a symbol of ultimate driver comfort, the Globetrotter trim levels include a full aerodynamic package, polished wheels, high-end seating, as well as a refrigerator, inverter, and parking cooler package.

Uncompromised Efficiency

The VNL series comes standard with the 13-liter Volvo D13 engine, while Daycab and VNL 400 models can spec the 11-liter Volvo D11 as an option. The 15-liter Cummins X15 is also available in the VNL series.

Both the Volvo D11 and D13 engines feature Volvo's patented wave pistons, a unique design that helps burn fuel more efficiently. Fuel is delivered by a proven common rail fuel system with proprietary features that improve fuel delivery precision, cut weight and reduce noise.

The Volvo VNL is also available with the Volvo D13 Turbo Compound (D13 TC) engine that utilizes a mechanical waste heat recovery system to capture wasted energy from the engine's exhaust. The result is an additional 50 horsepower fed back to the crankshaft and an improvement in fuel efficiency of up to 6.5 percent.

"Volvo's D11, D13 and D13 TC engines offer an incredible mix of power and efficiency," said John Moore, Volvo Trucks product marketing manager – powertrain. "For customers needing even greater fuel efficiency, our XE, eXceptional Efficiency, downspeeding packages are available and paired with the Volvo I-Shift."

The new Volvo VNL series not only turns heads on the road but also in the wind tunnel. Its sleek new design better controls airflow around the truck and its trailer, resulting in improved fuel efficiency. When combined with the efficiency benefits derived from the D13 TC, the new VNL delivers up to a 7.5 percent increase in fuel efficiency when compared to a 2015 VNL model equipped with a GHG 2014 D13 engine.

The Safety Leader

Now we back to the plant tour where our guide Rob Simpson, Director, Brand & Marketing Development continue to educate us about VNL's safety preparedness.

"Highway crashes are on the rise, which might be surprising because today's trucks much safer than before. What's happening is with greater highway congestion, aggressive driving, less experienced drivers, road rage we see fatalities, injuries and property damage on a rise. What are we doing about this? Let's look back to 1927 when Volvo founders recognized that transportation is about people and decided that safety will always be at Volvo the number one priority. We continue that with a vision that we want to see today that there are zero accidents. Is it possible? If you consider that 93% of all commercial vehicle crashes are caused by human error, there is a big opportunity for improvement, and it's what we want to focus on. What technologies can help the driver to be safer in a cab and those around him/her on a highway also to be safer?

There are few levels of protection. A Passive technology that protects the driver in the event of a crash – high strength steel cab of Volvo truck is the strongest cab in the world. But today we offer Side Roll Protection System integrated into a driver seat. Great technology is developed initially for a fire and ambulance vehicles. We are proud to bring it to the truck world. Here how it works: a roll defector in a seat detects when the vehicle is about to roll. Within a quarter second three things happen – first the seatbelt tightens to hold driver secure in a seat, the suspension drops so the driver has more survival space overhead, and then airbags deploy providing a cushion for the driver's head and neck.

Let's talk now about active protection. 81% commercial vehicles crashes are caused by passenger cars. There is a calculation that only one additional second of warning to the driver before an accident happens is reducing the probability of front end collision by 90%. We thought how to give the driver that extra warning. We've have introduced LED lights all over the truck, - headlights, turn, marker and parking lamps. The brighter LED lights design project further down the road, they allow the human eye to pick up and identified objects more easily. They have also tuned the way to project more light onto the right shoulder and to allow far less light into the cab from the upcoming traffic. Although they are not dynamic, they are tuned to the truck, so they are very focused, clean lights. They are eventually helping to reduce a driver fatigue.

And then we have advanced collision vehicle technology called Volvo Active Driver Assist combined with Bendix Wingman Fusion. This is standard on all VNL and VNR models. With camera and radar integrated it's monitor distance and speed of the vehicle or object ahead and gives an extra warning to the driver. The driver receives an audio warning signal following by red light flashing on a windshield. If the driver does not react to the warnings in a timely fashion, then the technology involves by reducing throttle, disengaging cruise and applying brakes to reduce the severity of impact or prevent it altogether. The study shows that technology like this reduces the probability of a collision by 80%. The average cost of a commercial truck crash is USD 110K. If you think about this technology as the return of investment, we believe this is huge. The payback is about 4-5 months. But most important – by implementing Volvo Active Driver Assist, we're helping the driver to be safe. Trucking business is about hauling trade, but first, it's about people. With the drivers' shortage, these days we like to be sure that our customers have all tools needed to keep their drivers safe. That why we committed to a zero accidents policy. We are not there yet, but I believe, one day we'll be there.

Superior Connectivity

Ashraf Makki, Volvo product marketing manager – technology took his turn to speak about uptime improvement on new Volvo trucks.

"As they say, if the truck's wheels are not turning, truckers are not earning! – We at Volvo do remember this mantra very well. Therefore, so important to reduce downtime and maximize the uptime. 2.3 days – this is the industry average of the downtime that truck spent at the dealer for a software or a parameters update. The job that takes literally about 30 minutes. If we put a dollar figure to this, we estimate $1100 per day for a truck downtime. 75% of the trucks running down the highways do not have the latest software update for that reason. They do not want to lose money on a truck sitting idle at the dealer waiting for the software update.

That's why we're introducing Remote Programming. By using this technology, the customer doesn't need to send a truck to a dealer for a software update. What customer has to do upon receiving a message about software update is call our call center to book an appointment. Then park the truck in any safe location, turn off the engine while leaving the key in "on" position, and wait about 30 minutes for a job being done remotely over the cellular network. Compare this with 2.3 days of productivity loss at the dealership and calculate the savings.

We are literally defying our future, and we are in control of shapes of trucks to come", - concluded Ashraf Makki.

"The Shape of Trucks to Come" – it's how the organizers called the VNL presentation event. There is not much exaggeration in this title as Volvo is continuing to be on the edge of modern technology and innovation while sticking to its core values. I did ask Rikard Orell, Design Director of Volvo Trucks what's the story behind the distinctive Volvo diagonal bar that every Volvo truck or car proudly bears these days?

"Simple thing, - he answered. Our engineers of older days decide how to affix the Volvo circular logo to the grill, and figured out that to place it together with the bar will be simple, reliable and attractive". No more, no less.

Newspaper about

Newspaper about